1990’s

Founded in the mid 1990’s from a blank sheet of paper, APEX is a woman owned corporation focused on CNC Swiss machining technology. The company was founded after separation from a family machine shop, E. B. & Son Machine, who made upset forging dies for department of defense applications since 1968.

The company purchased the machine shop assets of the Saragraft Company, Pittsburgh, PA founded by accomplished machinist John Uptegraff, a Westinghouse shop manager who also manufactured tool & die components for Westinghouse.

Initial projects focused on military prototyping and production of aerospace optical lighting components.

Achieved Defense Logistics Agency (DLA) IDIQ contract for the F18, F404 engine components for direct supply to the United States Navy.

2000’s

Association with the late Congressman Jack Murtha, Chairman of the Defense Appropriations Committee, enabled APEX to network and participates with large defense primes seeking small woman owned business suppliers.

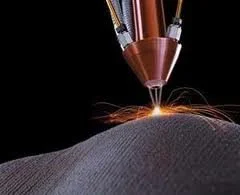

Expanded into laser photonics, Raman amplifier defense market with project runs over 10,000 pieces, running lights out to develop CNC Swiss unattended automation processes with a record of 76 hours.

Secured APEX Tier I supply chain status with one of the nation’s top 100 defense contractors, a global leader in night vision optics for small weapon systems and UAV’s.

Invested over $1 million in capital to expand to 20 spindles and opened a second facility in Latrobe, PA over 30,000 sq. feet to meet post 9-11 weapons surge producing over 200,000 annual components for missile, small arms, aerospace and medical applications.

APEX cofounder Chuck Fluharty was selected by the National Center for Defense Manufacturing and Machining (NCDMM) organization to participate in annual technical symposium for the National Defense University, Dwight D. Eisenhower School for National Security and Resource Strategy (Part of the ARMY War College). Chuck served for 10 consecutive years reporting on advanced manufacturing, automation, 3D printing and work force development. He was awarded two challenge coins for his contributions.

2010’s

Expanded into 3D additive manufacturing with desktop filament systems and powder bed fusion technology.

Restructured assets by selling all CNC equipment older than 2006 for $1 million in new equity to focus on CNC Swiss machining.

Added turnkey finishing including heat treating, anodizing, and chemical surface finishing services.

2020’s

Expansion into complete customer component subassemblies for APEX internally manufactured parts.

Continuation of micro machining and CNC Swiss automation exclusively with CNC Swiss technology.

Building expansion to 12,000 square feet including clean room assembly, office and conference center.